The intelligent Materials Tracking and Traceability software (iMTATs) enables organizations in the food supply chain to comply with the regulations issued by the US Food and Drug Administration (FDA) for compliance with the Food Safety Modernization Act (FSMA) without drowning in paperwork.

iMTATs can also minimize the paperwork required for tracking compliance with the Safe Quality Foods Initiative (SQFI) and the Hazard Analysis and Critical Control Points (HACCP) initiatives.

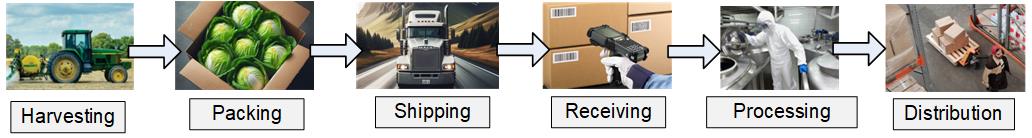

The Food Safety Modernization Act (FSMA) requires that organizations in the food supply chain record standardized Key Data Elements (KDEs) at Critical Tracking Events (CTEs) along a product's journey. Organizations handling materials on the critical foods list are required to send this data, in the form of sortable Excel spreadsheets to the FDA, the CDC, or other public health authorities, upon demand, within 12 hours.

While these spread sheets can be filled out manually, which is a boon to really small organizations in the food supply chain, manually entering this data and then keeping track of all the resultant spreadsheets, quickly becomes a labor intensive process. In our experience, for a typical mid-sized organization, this can require the loaded labor of between one and five full-time-equivalent people, at each site, at a loaded labor cost of over $6,000/month each.

In addition, it is easy to make mistakes, or forget an entry, when manually entering data, which can result in failed compliance audits and also the unnecessary recall of perfectly good product.

iMTATs solves these problems by using barcode and RFID scanning to automate the capture of the required data into an event tracking database from which the sortable spreadsheets can be printed upon demand.

iMTATs can also perform backwards traceability from defective products to suspect raw materials and forward traceability from contaminated or defective materials to finished products and who they were shipped to. This make it easier to decide which spreadsheets are relevent to a specific food poisoning outbreak.

iMTATs also automates the printing of GS1 compliant barcode labels, such as containing GTIN, LGTIN, and SSCC barcodes to save time and prevent mistakes that could result in rejection by their downstream supply chain recipient.

While automated exchange of materials tracking and traceability data is no longer required under the FSMA, many larger organizations in the supply chain, such as large retail and restaurant chains require that materials traceability data be sent to them in the form of EDI856 ASNs or EPCIS files. iMTATs automates this process, again with significant labor savings.

The iMTATs software:

In addition, the iMTATs software provides a real-time overview of the status of inventory, work-in-process, equipment, labor, quality control, customer orders and shipments.

Please click on the following link for more information about the Application of the iMTATs software to Food Processing.

| Features | Software |

|

Architecture | Background |

| Benefits | White Papers | FDA/GS1 Compliance | Videos | Partner Info |

| Software |

|

Architecture |

| Background | FDA/GS1 Compliance | White Papers |

| Partner Info | ||

| Features | Software Prices | Benefits |

Copyright © 2024 Smart Operations Management LLC